jrsavoie

Recruit

Can you guys help me with everything I need for a fuel pressure gauge?

Thanks

Thanks

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

modmafia.com

modmafia.com

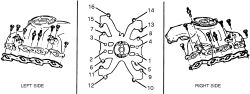

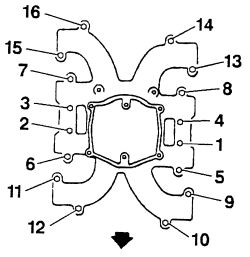

Fig. 11: Intake manifold bolt tightening sequence-1988-95 diesel engines

Fig. 11: Intake manifold bolt tightening sequence-1988-95 diesel engines

I was hoping to find a smaller gauge than what I have. I have a combo digital dial, normal sized gauge.I too have been looking at electronic fuel pressure gauge kits.

I just dont know what a good brand name is.

Used to be Stewart Warner was the go to company but I know knottt now.

That's the question I need answered also. I've always wished. There was a kit to get at least to the sending unit and incoming fuel line.So with the adapter fitting, are there any other fittings or adapters we need to thread this into the IP on ether a DS4 or DB2? and then to the barb for the hose? it looks like this fitting is a 6an male to female. iirc the fitting the screen is attached to on the DS4 is female o-ring boss.

No idea. Now knowing that's an issue, It's something I need to consider.I plumbed my electric auto meter sender at a Tee and my needle bounced a lot that I believe shortened the life of the gauge. Are you going to put a length of hose so you get a decent sized air air pocket to dampen the pulsing pressure or use a Snubber adapter of some sort?

modmafia.com

modmafia.com

www.glowshiftdirect.com

www.glowshiftdirect.com

www.glowshiftdirect.com

www.glowshiftdirect.com