Pepperidge

Member Advocate

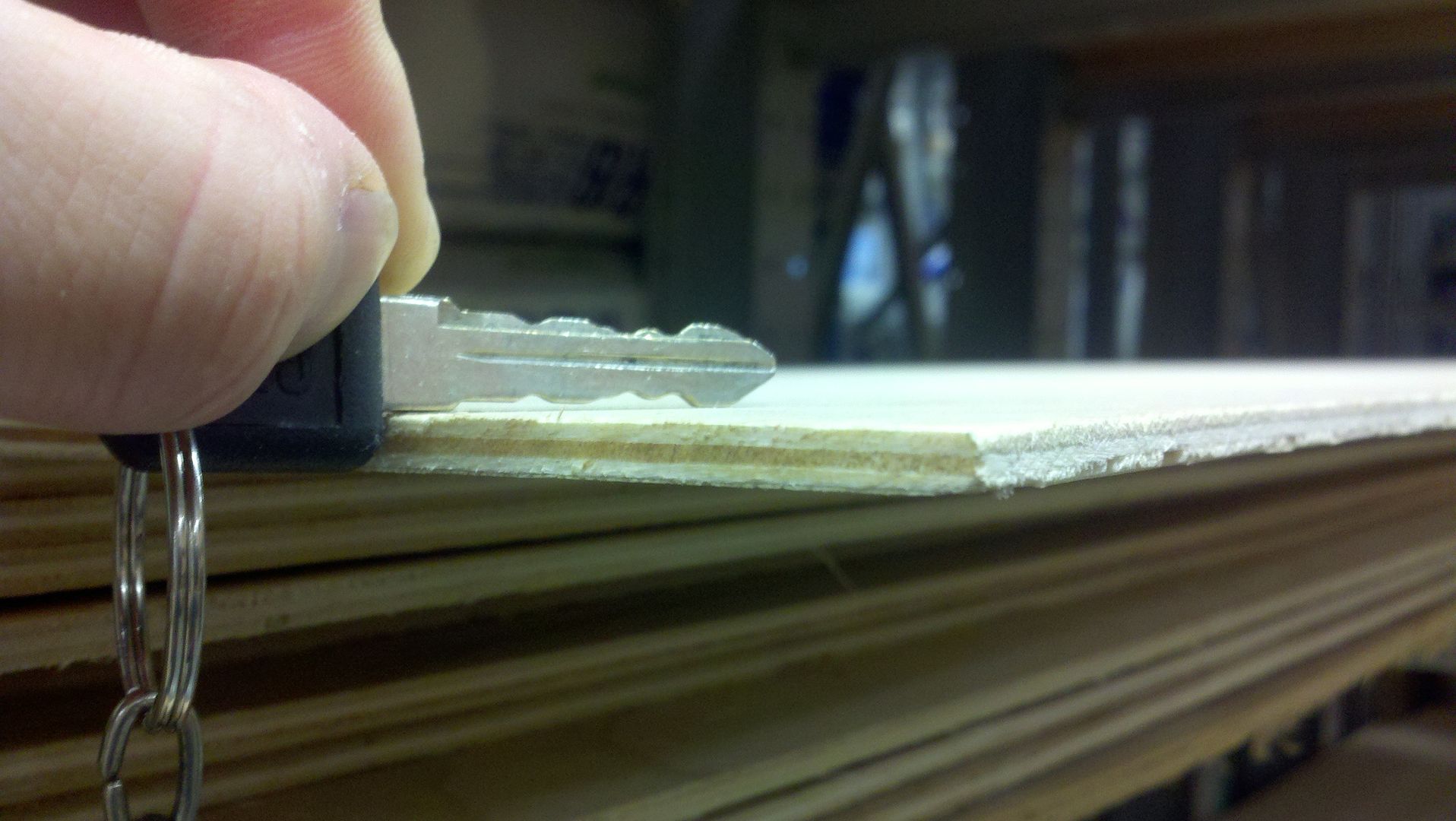

Pepp, your current bulbs are a 921, which has the same base as a 194 auto bulb. Using a replacement 194 like linked above isn't going to give you much light output being as the light is straight out the tip. You want something like this. Still going to run you a few $$ http://www.ebay.com/itm/White-12-LE...11-2-578-194-Ba9-194-/180689488034#vi-content

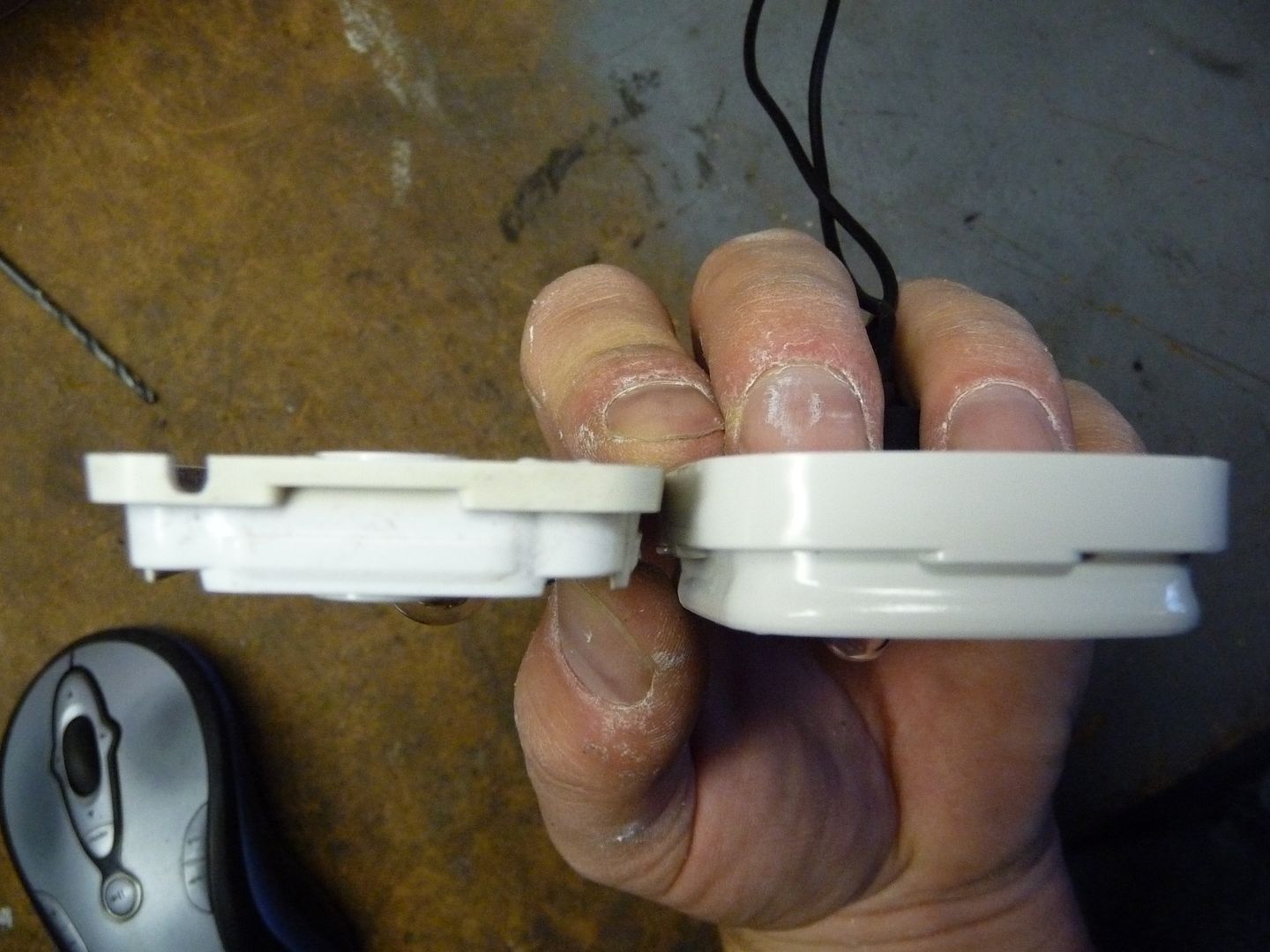

This is why I built boards for myself; so I could get the dual intensity and because they are outrageously priced. All in, I have about 4 hours of beer drinking time and $20 into the supplies that made 14 boards.

not sure about needing a dual intensity...in my case I figure thats why you can turn off one side of the light...I'm horrible at circuit board soldering...and I don't want to eliminate the factory bulb socket in case I need to switch back due to a failure...I'd like to buy whatever board would fit in my housing and some sort of plug in adapter similar to that auction...I'd give it a try myself with something like this and a socket adapter, but that board is $16...if you could help me come up with a parts list that wouldn't require too much soldering(even less and if at all possible none on the board) I might give it a try...