bobbiemartin

Author of The DB2 Conversion Guide

If you have been following my thread on installing an engine in our Suburban then you know how I got to this point. I'm going to use this thread to show the buildup of the GEP engine. Once its back in the Sub, I'll finish up that thread.

I bought this engine form a fellow Truck Stop poster that lives in Georgia. I knew it was a GEP engine and I figured it would be a good starting point for the new engine. I'm guessing this is an Optomizer 6500, but I'm really not sure what they call it. I'm sure it was made for an NA Hummer. It has all 24 volt parts on it and a hydraulic fan clutch. The front pulley and water pump have 4 V belt grooves. I'm not sure what the oil pan holds, but it looks bigger than a truck oil pan. Its hard to read the casting date, there is a small blob of metal obscuring the date code letter. However, looking at the heads, bearings and some other parts, they all have 2006 dates, so I think its a safe bet it was made in 2006.

The Valve Cover says it all, made by General Engine Products

And the valley has the diamond logo castings

The rear has the drain tube from the valley. 24 volt OPS and speed sensor, that stuff is made to last!

The front pulley and fan clutch

So that is the engine as I got it. I started taking it apart tonight. This is one clean 6.5. I really do not think this engine ever ran, if it did, it was not for long. Everything looks like new inside. A couple of the bores have some surface rust (I knew this before I bought it) but for all intents and purposes, its like new.

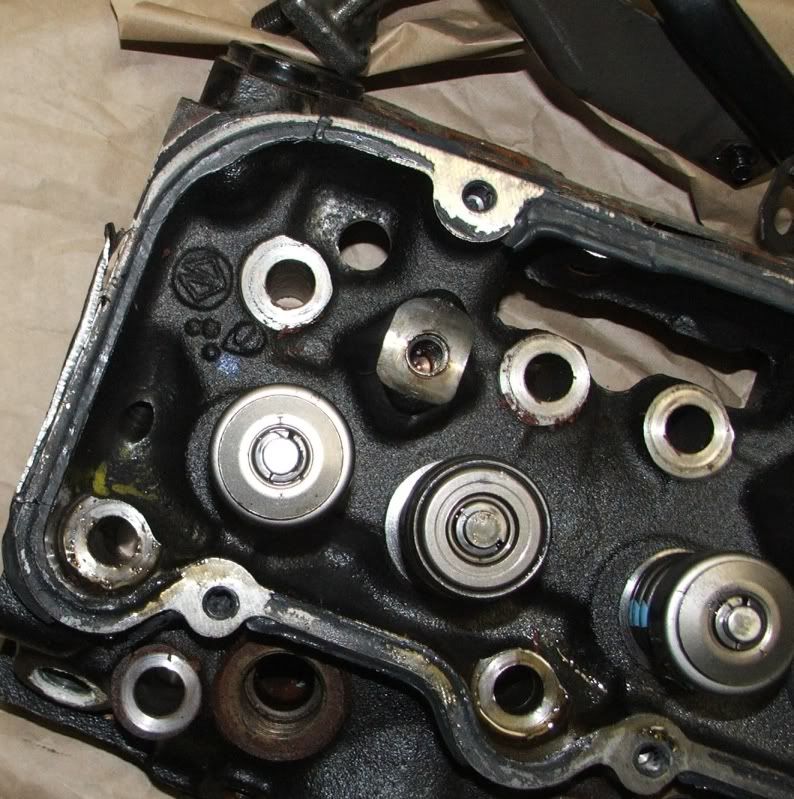

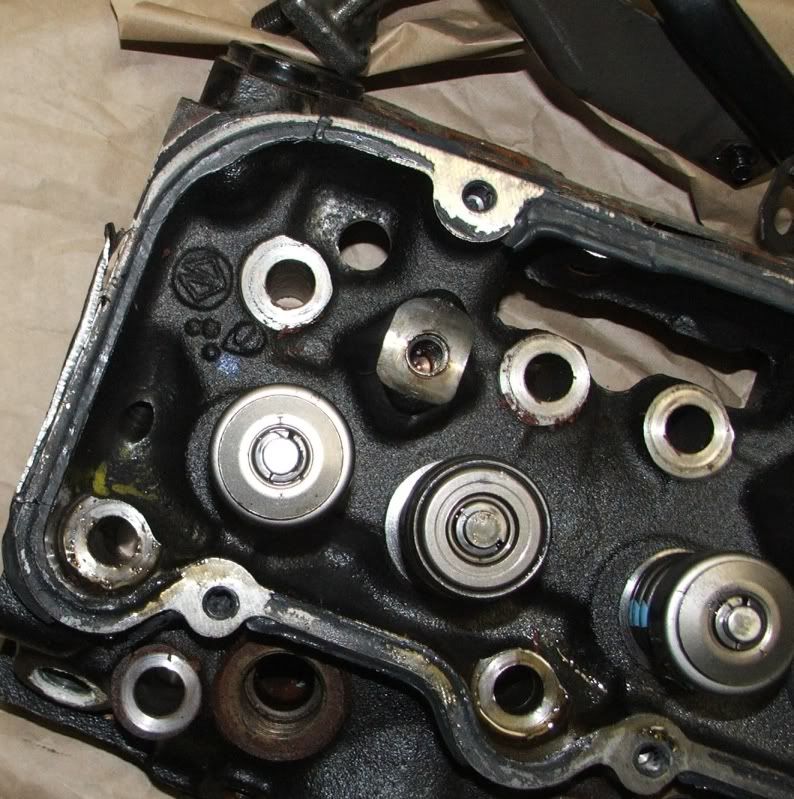

First thing I saw were these rockers. As you can see, they appear as new.

Diamonds cast in the heads as well. If I read the date codes right, these are 2006 castings.

A better shot of the heads. No wear visible on the valve stems. I'm telling you, this thing is like new.

A little rust on the bottom of the head, but should clean right up.

Front cover and cam front. Timing chain was removed before I bought it. Anyone know what that steel cover is for? My 95 didn't have anything like that. You can't see it, but it has an electronic type lower timing chain gear with the 4 triggers for the sensor. This engine had a DB2 and the crank sensor hole has a plug. I'm guessing they standardized all the engines to that style and just left off the sensor on the DB2 engines.

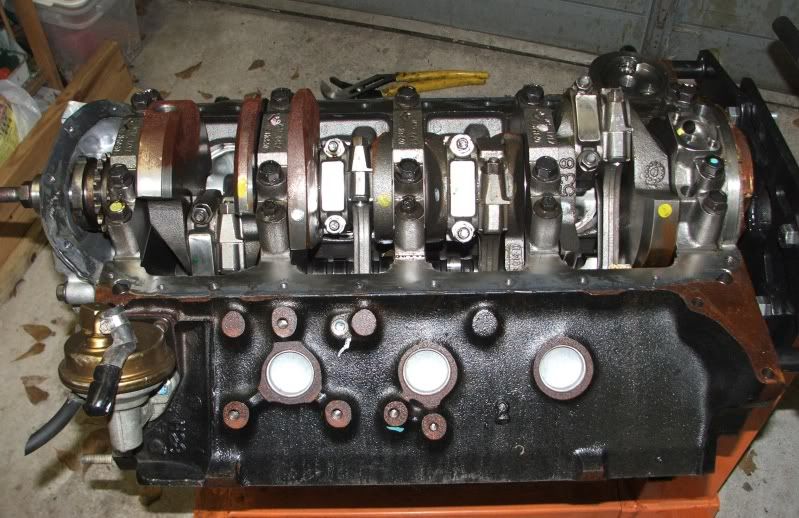

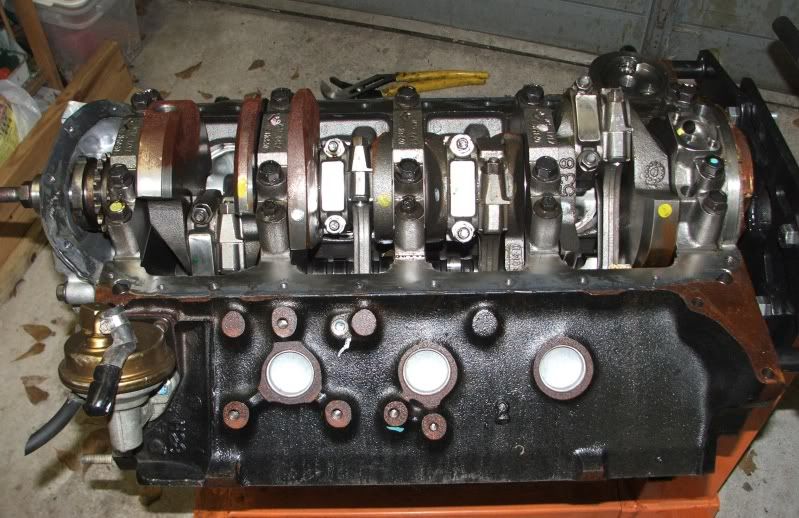

Bottom end shot. You can see the crank gear in this picture. A little rust on the crank throw, but it should clean up. Incidentally, this engine did not have a block heater, just freeze plugs.

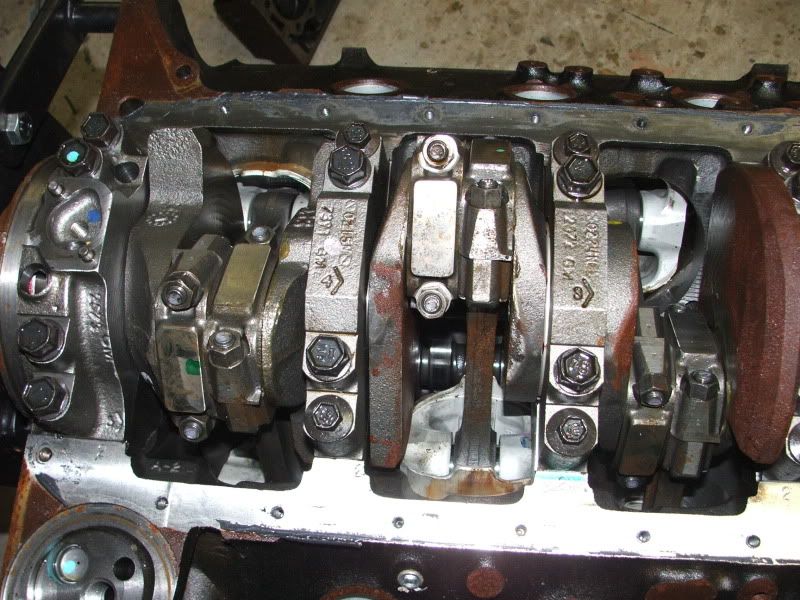

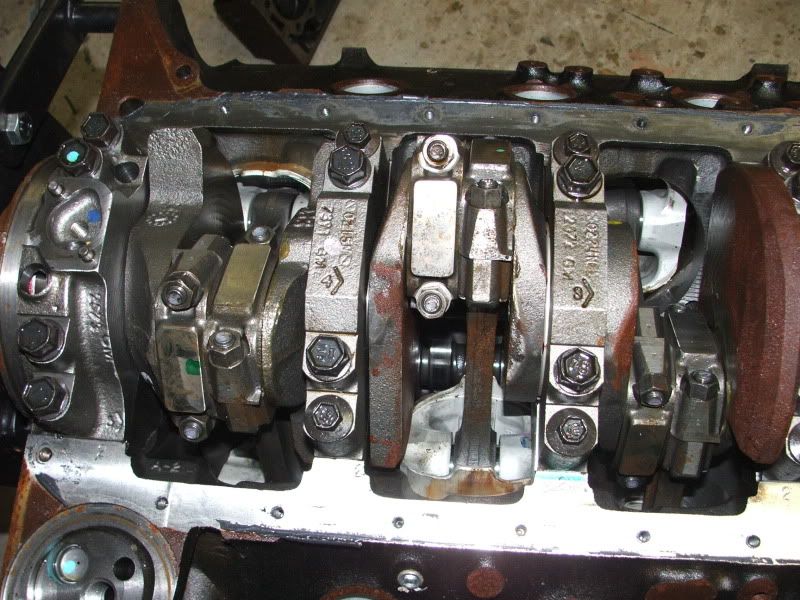

Close up of the crank & rods. No cracks in this block!

Well, that is all I got done tonight. Hope to have it at the machine shop by first of next week. I hope you find this somewhat interesting and I'll post another report one I get the block fully disassembled.

I bought this engine form a fellow Truck Stop poster that lives in Georgia. I knew it was a GEP engine and I figured it would be a good starting point for the new engine. I'm guessing this is an Optomizer 6500, but I'm really not sure what they call it. I'm sure it was made for an NA Hummer. It has all 24 volt parts on it and a hydraulic fan clutch. The front pulley and water pump have 4 V belt grooves. I'm not sure what the oil pan holds, but it looks bigger than a truck oil pan. Its hard to read the casting date, there is a small blob of metal obscuring the date code letter. However, looking at the heads, bearings and some other parts, they all have 2006 dates, so I think its a safe bet it was made in 2006.

The Valve Cover says it all, made by General Engine Products

And the valley has the diamond logo castings

The rear has the drain tube from the valley. 24 volt OPS and speed sensor, that stuff is made to last!

The front pulley and fan clutch

So that is the engine as I got it. I started taking it apart tonight. This is one clean 6.5. I really do not think this engine ever ran, if it did, it was not for long. Everything looks like new inside. A couple of the bores have some surface rust (I knew this before I bought it) but for all intents and purposes, its like new.

First thing I saw were these rockers. As you can see, they appear as new.

Diamonds cast in the heads as well. If I read the date codes right, these are 2006 castings.

A better shot of the heads. No wear visible on the valve stems. I'm telling you, this thing is like new.

A little rust on the bottom of the head, but should clean right up.

Front cover and cam front. Timing chain was removed before I bought it. Anyone know what that steel cover is for? My 95 didn't have anything like that. You can't see it, but it has an electronic type lower timing chain gear with the 4 triggers for the sensor. This engine had a DB2 and the crank sensor hole has a plug. I'm guessing they standardized all the engines to that style and just left off the sensor on the DB2 engines.

Bottom end shot. You can see the crank gear in this picture. A little rust on the crank throw, but it should clean up. Incidentally, this engine did not have a block heater, just freeze plugs.

Close up of the crank & rods. No cracks in this block!

Well, that is all I got done tonight. Hope to have it at the machine shop by first of next week. I hope you find this somewhat interesting and I'll post another report one I get the block fully disassembled.