ak diesel driver

6.5 driver

94 should be able to do the paperclip method

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Reading the first post, sounds like the 93 was the other truck that was overheating, which also sounds like it was a gas engine, that truck is on the back burner.I believe the OP mentioned it's a 93 but has a DS4 IP on it.

Trying to use either a snap on graphing scanner or a actron both obd2 so I bought adapterwhat scanner are you using?

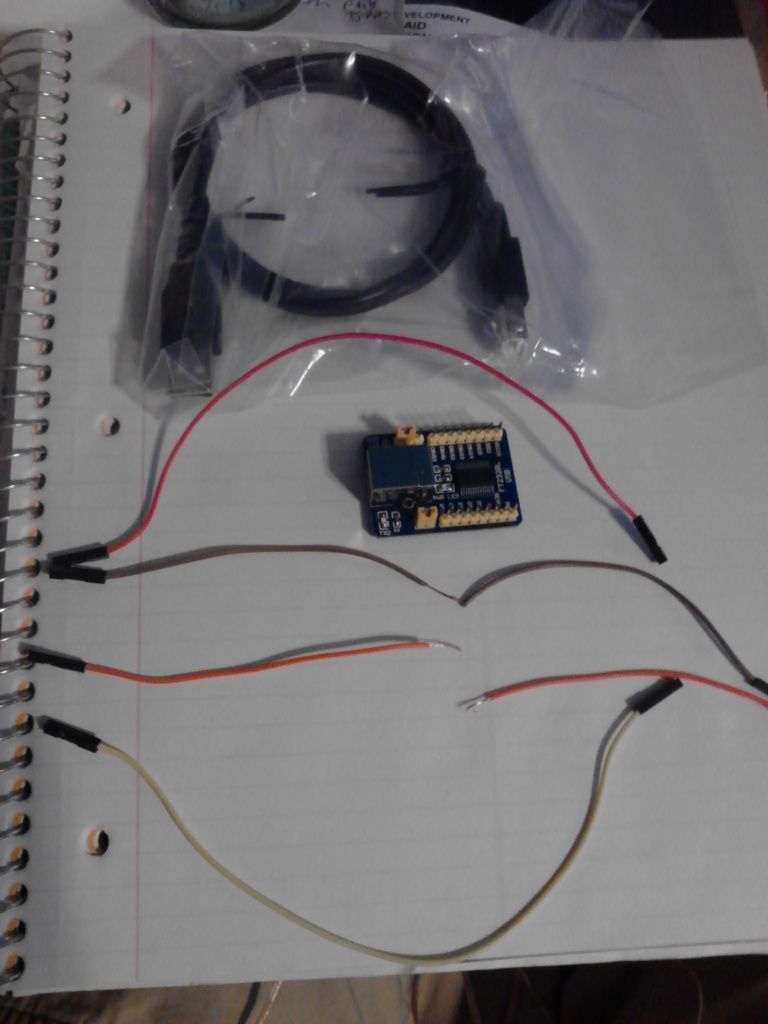

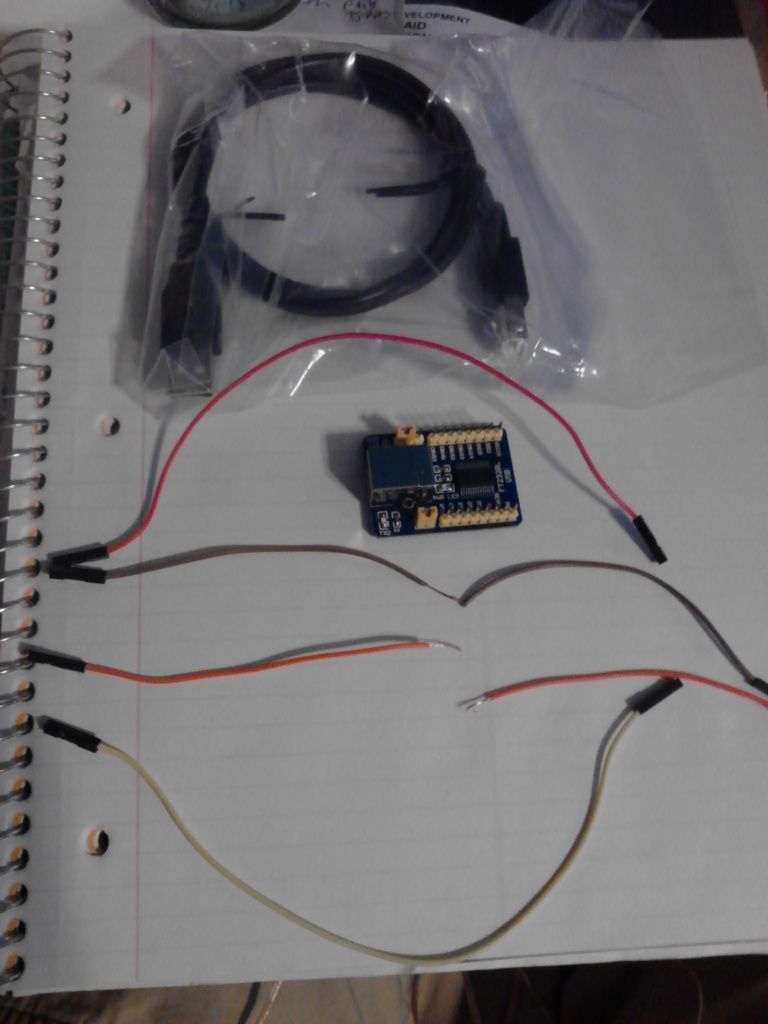

OK thanks for the info il check the links because I'll have to set TDC I assume I looked into the gmtd a couple weeks ago and got hacked so I was iffy about attempting again somebody said it's all done with scanners nowHonestly I never had any luck with the paperclip method on my 95. although that was before I replaced the PCM. I have not tried it with the 94 PCM I have in it now. But I can tell you how to build your own USB cable with a $15 part off amazon and a free program for your windows laptop that should communicate with it. I had no issues with it myself and ended up investing into the licensed version of the program to have the extra features.

Here is how to do it.... to build your own cable. follow the DP link and order the part linked in the amazon link. then setup the software from GMTDscan (free version) the software will allow you to read and clear codes, see live data and a few more things without paying anything. if you want to set the timing after an IP replacement you will need to pay for the license.

Link to building the cable... Note: if there is an issue cross posting this forum link Please let me know. I can copy and paste the main details here instead.

How To: Scan your OBD1 6.5 for less than $10!

Ok, first off, most of us know you can download GMTDScan from http://www.enghmotors.com/ and buy an ALDL cable that supports 8192 baud communication and scan your truck....but the cables seem to run $55-$75 and up! Which I found a bit silly.....if its a cable, then you can build your...www.dieselplace.com

the USB part you will need from amazon...

windows drivers for the USB amazon part... Note: you want both the VCP and V2xx drivers and set the device to com port 1 or 2 in the device manager. it's a limitation of the GMTDscan software that needs to be on com 1 or 2.

Drivers - FTDI

ftdichip.com

download GMTDscan basic version here... the licensed version is $100 on their website. I purchased it directly from them and a license was emailed to me.

Download – GMTDScan

www.gmtdscan.com

If You are going to send that plastic intake cover to the trash bin, send it over to here.Welcome to TTS..glad you joined.. I'm sure Mr Marty or one of the others can help you with the routing problem.. I don't have a diagram for it. I will say that plastic piece that says turbo power on it, belongs in a garbage can.. don't leave that on the truck..

But if you are new to 6.5 turbo diesel engines you have definitely found the right place. These guys are a world of knowledge

The harness isn't that expensiveNo I don't believe it does just a buss bar I think it's called with inline fuses I'm pretty sure i wasn't getting power to the crank position sensor so I tore rest if wire loom off and it doesn't look real good and how could oil leak from ports or bolt hole on intake I didn't have in? Maybe I should slow this project down and just wait until I can buy a new harness View attachment 80228View attachment 80227

Do you have a link to the hf hand held bead blaster?Is there a lot of bare wires, broke, cut and stripped wires ?

If not, unplug the terminals and look into them, use a maggit flying gass, ooops, magnifying glass, look into each individual end. If there is corrosion, clean them up. One of those hand held bead blasters from HF does an amazing job of shining up them connectors.

Just be sure that there is no way the beads can enter into the engine or the injection/fuelnsystem.

That one will work just fine.Do you have a link to the hf hand held bead blaster?

What media do you use?

This?

Harbor Freight Tools – Quality Tools at Discount Prices Since 1977

Harbor Freight buys their top quality tools from the same factories that supply our competitors. We cut out the middleman and pass the savings to you!www.harborfreight.com

If You know someone that has a glass bead cabinet, maybe they would give You a coffee jug of beads.Do you have a link to the hf hand held bead blaster?

What media do you use?

This?

Harbor Freight Tools – Quality Tools at Discount Prices Since 1977

Harbor Freight buys their top quality tools from the same factories that supply our competitors. We cut out the middleman and pass the savings to you!www.harborfreight.com

I thought maybe a trip to New Orleans or Jerry Springer for beads.If You know someone that has a glass bead cabinet, maybe they would give You a coffee jug of beads.

That would last quite a while, maybe.