FellowTraveler

Well-Known Member

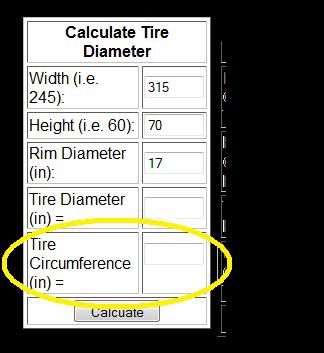

You might want to measure your actual loaded tire height from road surface to center of hub, I suggest this because its critical in final calibration.

The tire you have 23585/16 equates to 31.73" diameter average however a loaded tire maybe 28" (as example) there various debates about this however; I have always had to adjust for the smaller diameter of the loaded tire (s).

I'm running 295/75/16 advertised as 33.5" loaded they are 31.5" "loaded measurement requires tire to be on proper width wheel and the entire thread contacting the road surface (tarmat).

The tire you have 23585/16 equates to 31.73" diameter average however a loaded tire maybe 28" (as example) there various debates about this however; I have always had to adjust for the smaller diameter of the loaded tire (s).

I'm running 295/75/16 advertised as 33.5" loaded they are 31.5" "loaded measurement requires tire to be on proper width wheel and the entire thread contacting the road surface (tarmat).