Blue-canoe

Member

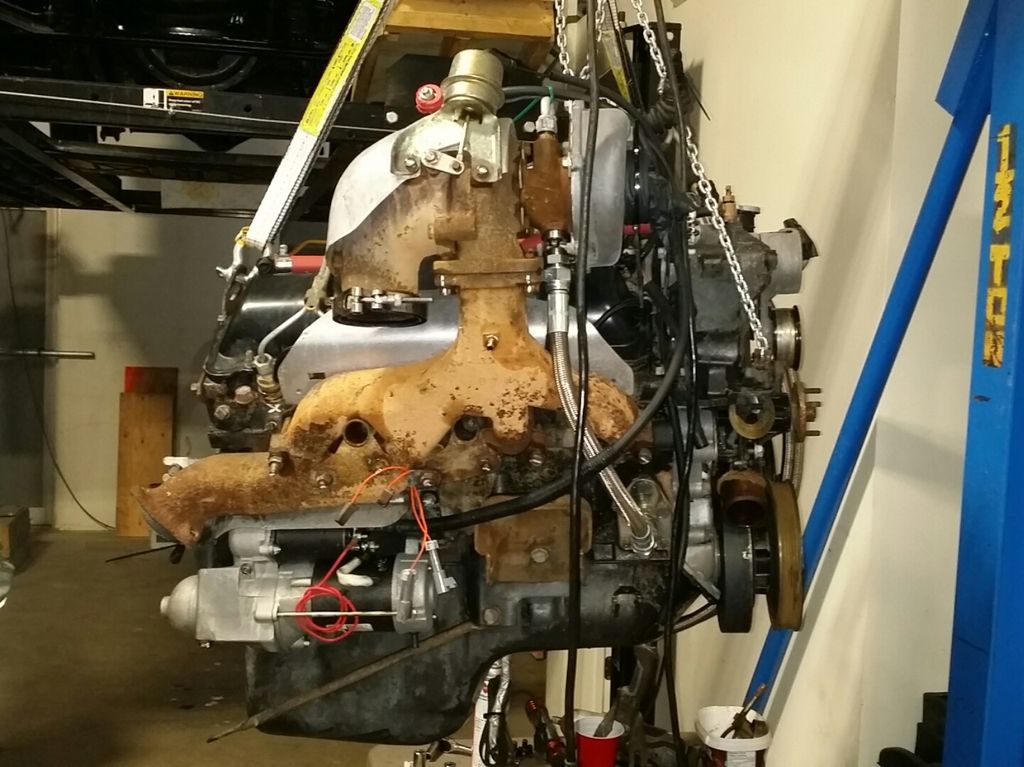

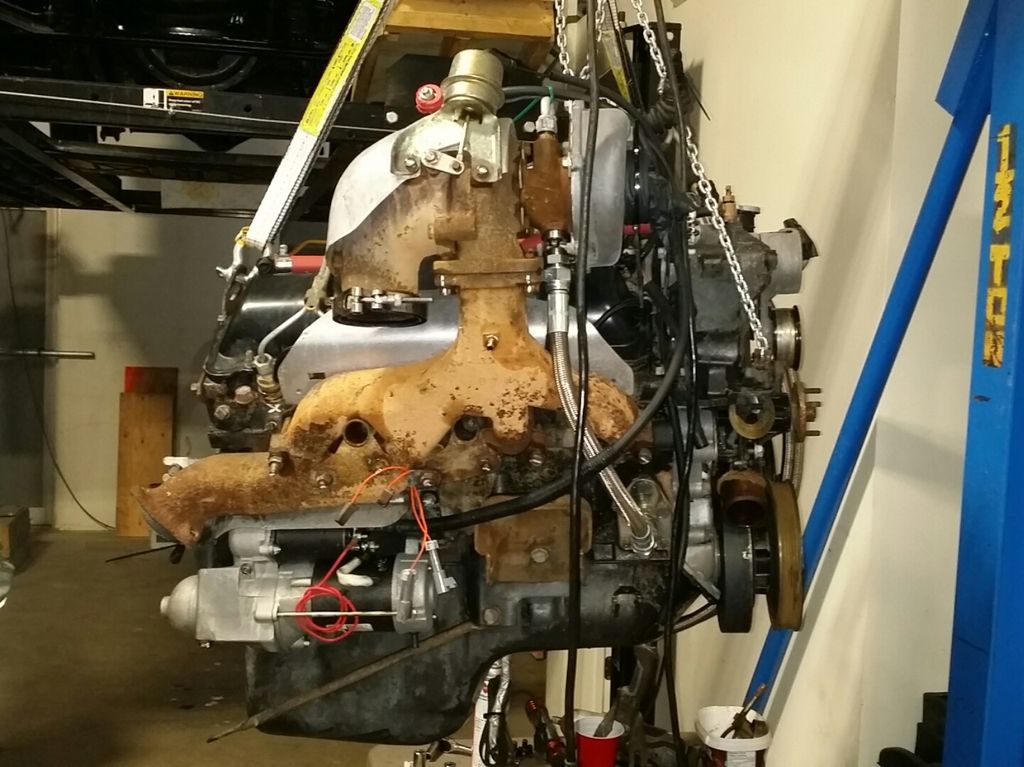

Engines almost ready

New mounts, cleaned up wiring

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Snazy. I suggest pulling the glowplugs out before install. When it is time to fire up, cranking the engine over a million times with no plugs in there will let it bleed air out much easier and faster.

And before WarWagon says it- loose the fram oil filter. They dont filter well, no antidrain back valve, etc.

I can't see, do you have on the starter brace that mounts near the freeze plugs?

Wow, very cool to see of my products in use! thanks for posting.

As far as trans to engine make sure flex plate is on correctly (it will go on backasswards). Sometimes they mate right up and sometimes they are a little bitch. Last one I did literally fell into place the first time. Just gotta go for it and see if you made the 6.5 gods happy or not that day.

I have a 599 6.2 block sitting in the garage for parts that has a busted out part of the casting for a starter mount bolt. The block is scrap over the busted casting for the starter mount! GM's casting in the area is weak for a diesel thus making the starter brace critical. Ether use on that engine, clue to PO's abuse of impacted glow plugs, cracked 3 or more pistons and may be the cause of the casting breaking even with the brace - Don't use it! Fix whatever starting problem and include AAA towing service so you don't have the temptation to use IDI destruction in a can.

Crank the engine 30 seconds and then GIVE IT UP FOR 2 MIN minimum when priming the injection system. The 10+ HP starter will cheerfully melt down if abused and they are NOT fun to change warranty or not. Aside of priming the fuel system: These engines will light off easily or they have an issue that needs fixed. Sometimes you need more glow plug time aka try again. Or in your area gelled fuel or frozen batteries...

Jumper the lift pump to "ON" for the entire time attempting to start and or prime the fuel system. Check often for leaks.

I leave in the hardest to get to glow plugs on the passenger side aka 5 glow plugs out to prime the fuel system. I also have the throttle WOT. When I get a mist out of the glow plug holes the 5 go in and still WOT till it starts to fire then 1/2 throttle attempting to maintain 2000 RPM. This helps get the air out and keep it from stalling. You already have oil pressure from the cranking required to prime the fuel system. The DB2 governor has WOT and quickly closes as RPM comes up - DS4 electronics differ, but, I use the same startup procedure. (The DB2's I leave the cold advance off as it purges more air when it's off due to increased fuel return.)

Unlike the "religious" debates of what oil to use Oil filters as @Will L. notes are a surprise problem with The FRAM Group, who now owns lots of formerly top of the line filter brands, leading the way in not caring about their defective products and giving you a long drawn out claim hassle if their filter takes out your Cummins engine as a TDR member had happen. Post 24 is the link. http://www.thetruckstop.us/forum/threads/mobile-1-oil-filter-failure-or-defect.44531/

Tear-O-Lators: aka Boch made by Purolator, well, apparently failure IS an option. http://www.thetruckstop.us/forum/threads/bosch-purolator-oil-filter-failure.44117/

As the Walbro has a pre-filter 'gravel' screen in it, drop the tank and loose the clog/gel prone screen.

I do the vacuum pump delete via ATT turbo. Otherwise it's the same as a power steering pump pulley or Ford IDI vac pump: long bolt with washers. Special tools may be rented.

Yes, the back passenger side 3 GP's and that's 2/3rd due to the difficulty of getting the wires on in the heat shield tubes.

Not prime of the lift pump: I leave the lift pump on to prime the IP, lines and injectors while sitting via IP transfer pump leakage and cranking as some years are questionable IF they turn the lift pump on during cranking. Bad design, failures, WTF ever... It's just quicker to have the damn thing on period to get the engine to start. Then troubleshoot lift pump should run not run, was it wired properly, bad relay, OPS, etc. You know the usual trons headache.

Cranking cools off the glow plugs and prechambers. So once you have cranked it to where the IP has a prime the big thing is quick cranking bursts followed by reheating the self limiting glow plugs before attempting to crank to start again.

Do not use a battery charger with "start the engine booster" on as the voltage from that setting will take out even self limiting plugs.

@Burning oil is correct the aftermarket tank socks do NOT have the bypass valve in them. Snot can be bugs in fuel, a complete disaster, if left uncorrected.

I just noticed the waterpump, then noticed your location.

Are you familiar with the differneces in waterpumps? Not as crucial where you live, but still a smart upgrade to keep passanger side as cool as the driverside.