great white

Well-Known Member

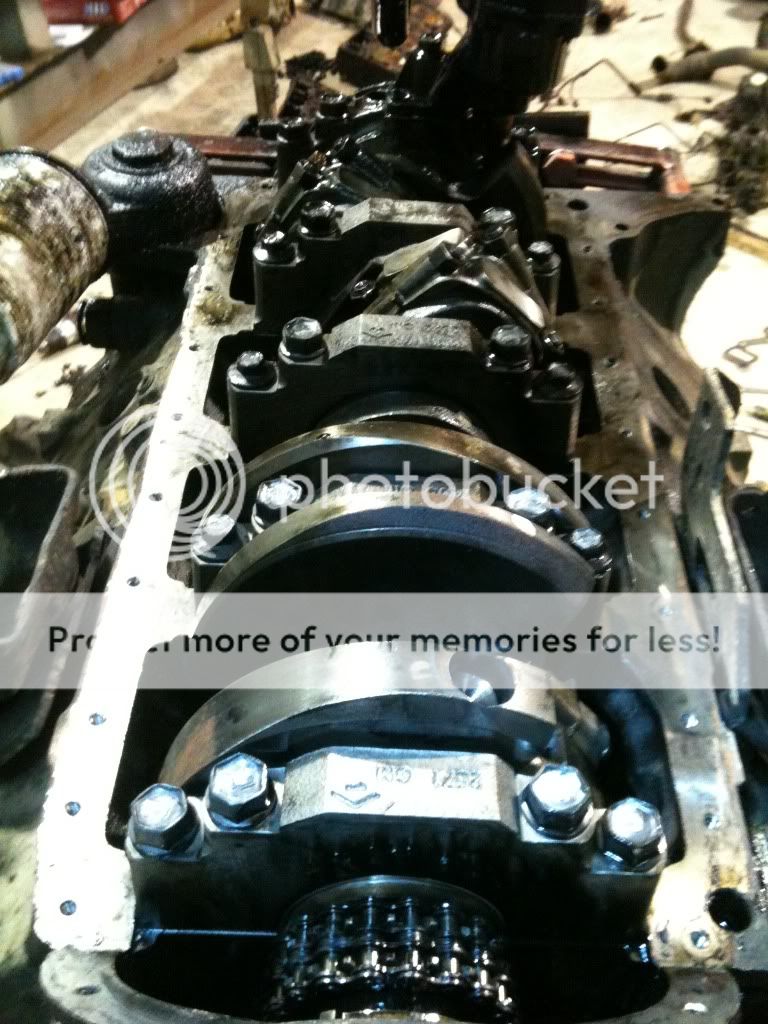

I have heard from the local machine shop that this can be fixed with a sleeve if the rest of the block is worth the coin.

True, cylinders can be sleeved.

But I don't think I would bother with a 6.5.....not "worth the coin"