dbrannon79

I'm getting there!

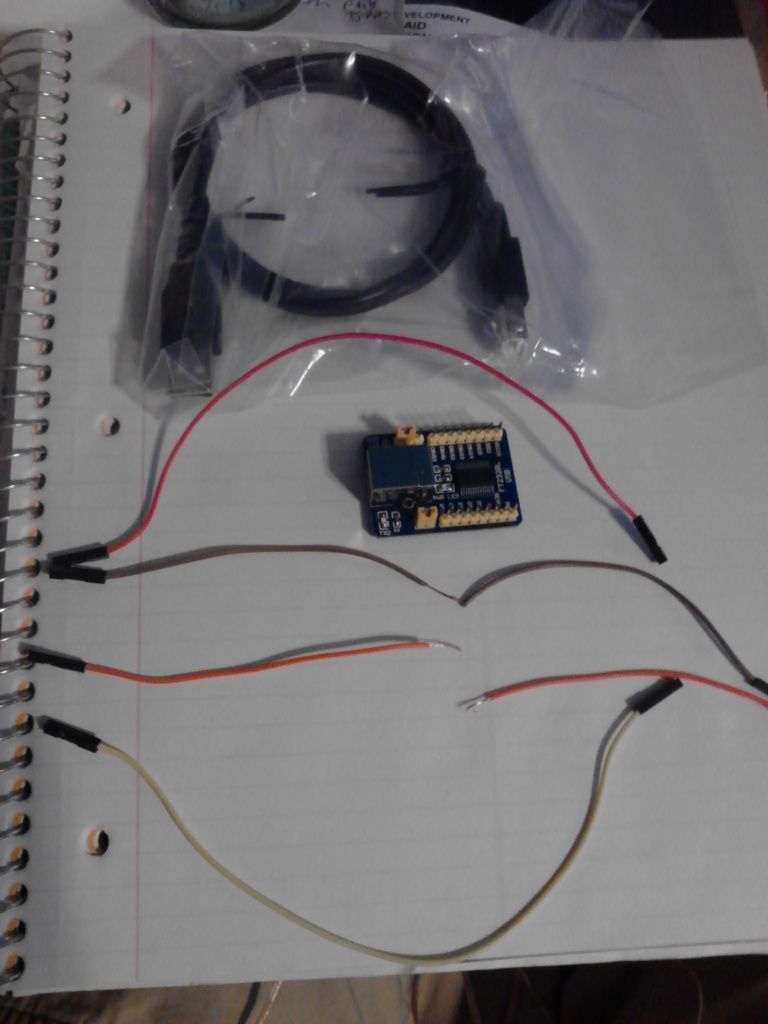

for OBD1 there are very few. depends on what you want to spend. I use some software on my laptop called GMTDscan with a homemade usb adapter. the software is free but if you want to time it, you have to purchase a license for it that costs $100. it will also do just about everything that the tech 2 will do but is built specifically for the 6.5 diesels. it won't work on other gassers. if you are interested, I can provide some links to the $15 device I ordered off amazon to connect to the PCM through the USB on the laptop and where you get the drivers for the device.

google search "how to read codes on 6.5 diesel under $10" look for a thread posted on the DP forums. credit goes to the guy that made that thread, but it works. the device only uses two wires on the PCM connector, I always leave mine connected to the truck and have the USB hidden in the dash. when I need to use it, I just pull the laptop out, dig the USB out of the dash and connect. keeps me from misplacing stuff LOL.

google search "how to read codes on 6.5 diesel under $10" look for a thread posted on the DP forums. credit goes to the guy that made that thread, but it works. the device only uses two wires on the PCM connector, I always leave mine connected to the truck and have the USB hidden in the dash. when I need to use it, I just pull the laptop out, dig the USB out of the dash and connect. keeps me from misplacing stuff LOL.