red

Being a lake bum in Texas

Helped out a couple friends today with some heavy lifting. This old tool trailer was used as a parts donor for his other one and is just about ready for scrap. Since I was in the area....

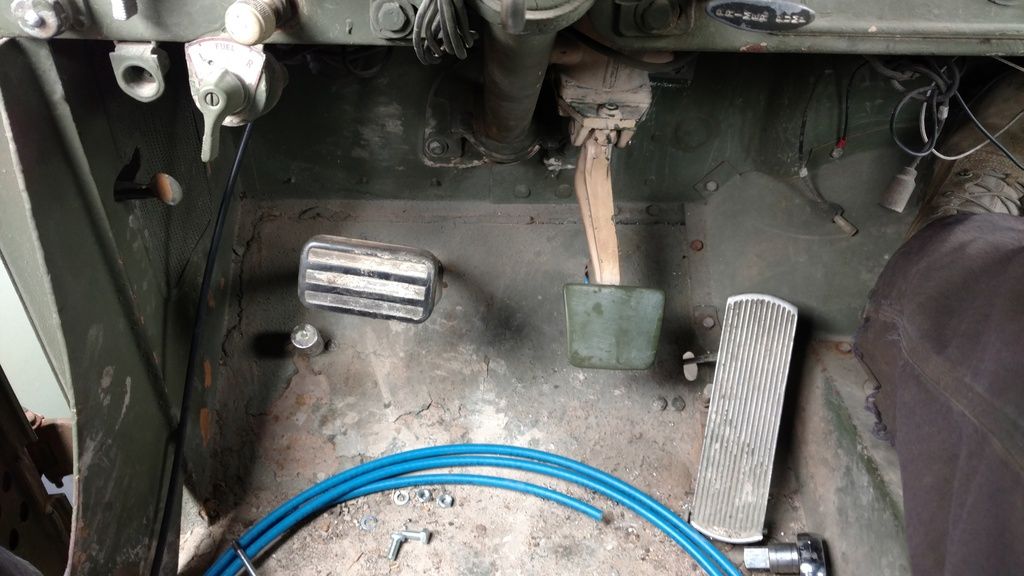

Went ahead and picked up the last of the heavy parts from my old deuce and a half and loaded it onto the trailer.

Earlier in the morning had helped another friend with his truck. Needed to lift his engine a few inches for clearance when replacing the front main seal.

Went ahead and picked up the last of the heavy parts from my old deuce and a half and loaded it onto the trailer.

Earlier in the morning had helped another friend with his truck. Needed to lift his engine a few inches for clearance when replacing the front main seal.