ryanryan

New Member

I am thinking about buying a 220v welder. The problem is, I don't have any room left in my main panel in my house. The only alternative I can think of is that I have a sub-panel for my hot tub. It is a 60 amp breaker in the main panel and the sub-panel has 4 "poles", 2 of which are being used for the 60 amp for the hot tub and 2 are left open.

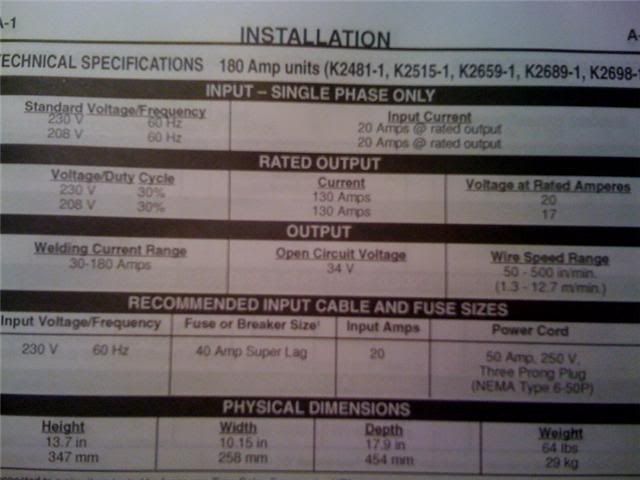

So my first question is, can I use a 40 amp GFCI, instead of a 30 amp GFI? I have multiple 40's available to me for free, but I don't know if that is bad for the welder or no(it is supposed to have a 30 amp breaker, which is minimum though correct, there isn't a maximum is there?)? If I could use this, what do I do with the "piggy" wire? Wire it into the neutral port on the GFCI, or connect it to the neutral bar on the sub-panel itself(like it is supposed to be)? The reason for this is because the welder has a 3 prong plug, with no neutral. Or should I just wire the neutral wire into the GFCI, like it is supposed to be, and just cap off the other end that will go to the outlet with a marrette connector?

If none of that will work, I will need a normal 30 amp GFI, correct? Can I use this in the Siemens sub-panel I have as long as it is a Siemens breaker?

Is there anything else I can do since my main panel is full?

Other info:

Main panel is Stab-lok, Sub-panel is Siemens, pics below.

P.S. Sorry for the long post, I just like to completely explain myself!... This is the welder,

http://www.canadiantire.ca/AST/brow...+Electric+MIG-Pak%AE+180+Wire+Feed+Welder.jsp

So my first question is, can I use a 40 amp GFCI, instead of a 30 amp GFI? I have multiple 40's available to me for free, but I don't know if that is bad for the welder or no(it is supposed to have a 30 amp breaker, which is minimum though correct, there isn't a maximum is there?)? If I could use this, what do I do with the "piggy" wire? Wire it into the neutral port on the GFCI, or connect it to the neutral bar on the sub-panel itself(like it is supposed to be)? The reason for this is because the welder has a 3 prong plug, with no neutral. Or should I just wire the neutral wire into the GFCI, like it is supposed to be, and just cap off the other end that will go to the outlet with a marrette connector?

If none of that will work, I will need a normal 30 amp GFI, correct? Can I use this in the Siemens sub-panel I have as long as it is a Siemens breaker?

Is there anything else I can do since my main panel is full?

Other info:

Main panel is Stab-lok, Sub-panel is Siemens, pics below.

P.S. Sorry for the long post, I just like to completely explain myself!... This is the welder,

http://www.canadiantire.ca/AST/brow...+Electric+MIG-Pak%AE+180+Wire+Feed+Welder.jsp