john o

New Member

well ive already started an figured id share on this site as well.

the truck- 96 gmc k3500cclb 4x4 dually former 6.5td

the donor- same but an 02 d-max 190k new injectors 20k ago

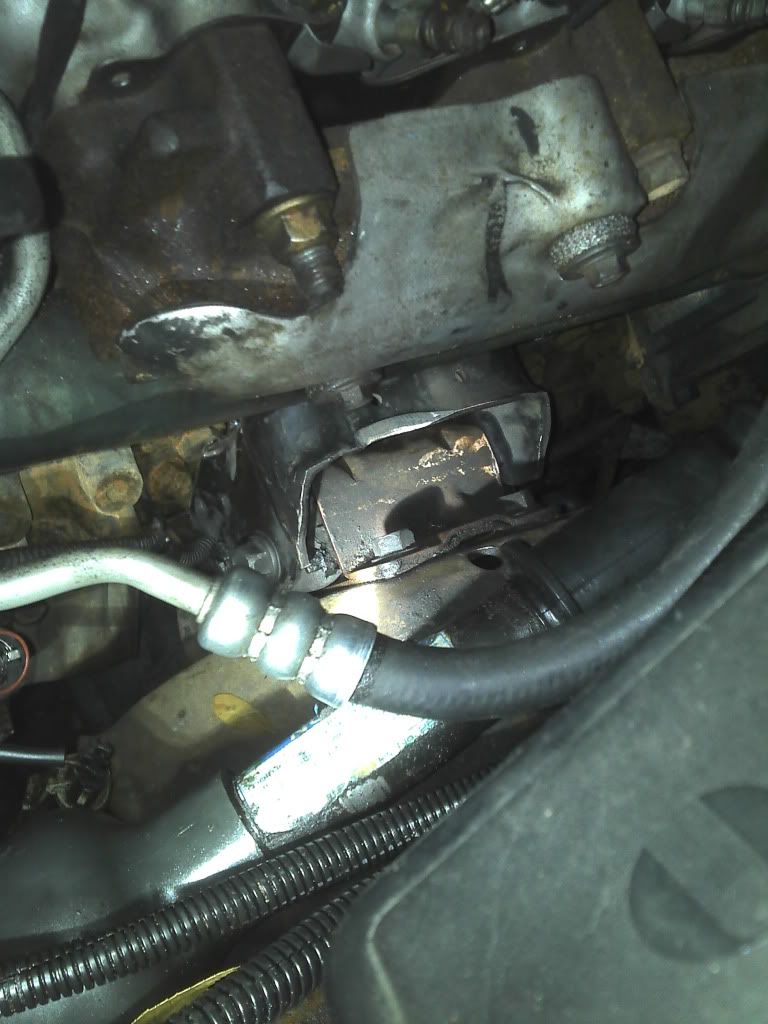

sic.5 out

my new parts collection

the truck- 96 gmc k3500cclb 4x4 dually former 6.5td

the donor- same but an 02 d-max 190k new injectors 20k ago

sic.5 out

my new parts collection