Anubis

Being fat sucks

Picked up this engine for $75 off Ebay ... cost me $35 in gas to go get it. I am calling this a 6.2/6.5 Hybrid ..... but it is actually going to be a 6.2 with a DS4 fuel system and a GM4 turbo......

looks like a pile of crap..... couldn't find the casting number..... it was beginning to look like my search for a block was going to continue.

Looks can be deceiving.

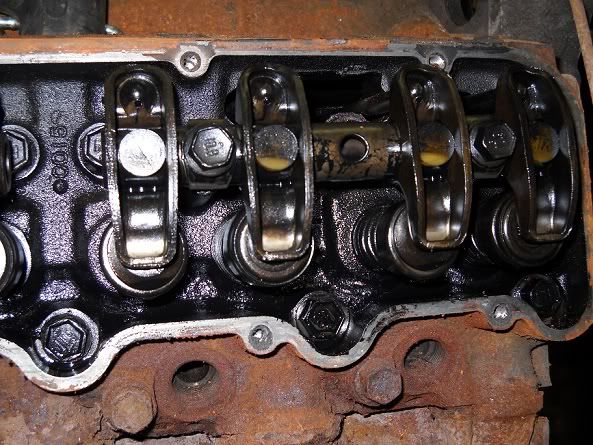

Passengerside with the valve cover off. Look how clean this is

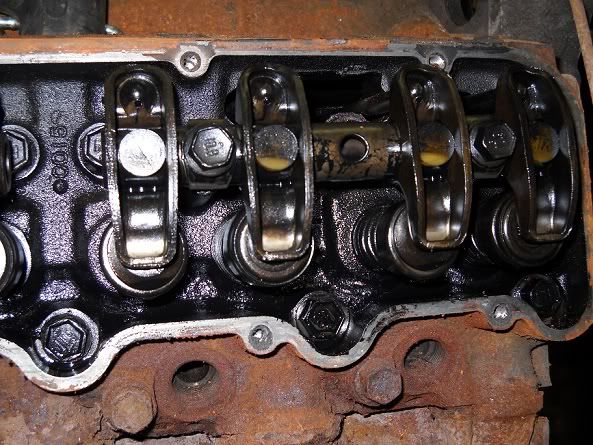

Driverside with the valve cover off.

After we (my brother was helping) got the heads off we put the short block on the engine stand.

look how clean this engine is considering it spent 10+ years in a shed.

This came apart 10x easier than I thought it would. Could not find evidence of a blown head gasket, no slop in the timing chain, and very little wear on the lifter bodies. As of yet I don't see any cracks, but I have to wait till the pistons are freed up to get the crank out........ it was nice of Detroit to hide that bolt behind the shield in the timing cover ........ Eventually found the casting number and it is a 660 block, can anybody tell me which pre-cups those are?

looks like a pile of crap..... couldn't find the casting number..... it was beginning to look like my search for a block was going to continue.

Looks can be deceiving.

Passengerside with the valve cover off. Look how clean this is

Driverside with the valve cover off.

After we (my brother was helping) got the heads off we put the short block on the engine stand.

look how clean this engine is considering it spent 10+ years in a shed.

This came apart 10x easier than I thought it would. Could not find evidence of a blown head gasket, no slop in the timing chain, and very little wear on the lifter bodies. As of yet I don't see any cracks, but I have to wait till the pistons are freed up to get the crank out........ it was nice of Detroit to hide that bolt behind the shield in the timing cover ........ Eventually found the casting number and it is a 660 block, can anybody tell me which pre-cups those are?