Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome to The Truck Stop! We see you haven't REGISTERED yet.

Your truck knowledge is missing!

- Registration is FREE , all we need is your birthday and email. (We don't share ANY data with ANYONE)

- We have tons of knowledge here for your diesel truck!

- Post your own topics and reply to existing threads to help others out!

- NO ADS! The site is fully functional and ad free!

Problems registering? Click here to contact us!

Already registered, but need a PASSWORD RESET? CLICK HERE TO RESET YOUR PASSWORD!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

motors motors motors

- Thread starter red

- Start date

red

Being a lake bum in Texas

You were right, had missed one, was hiding under some oil lol.

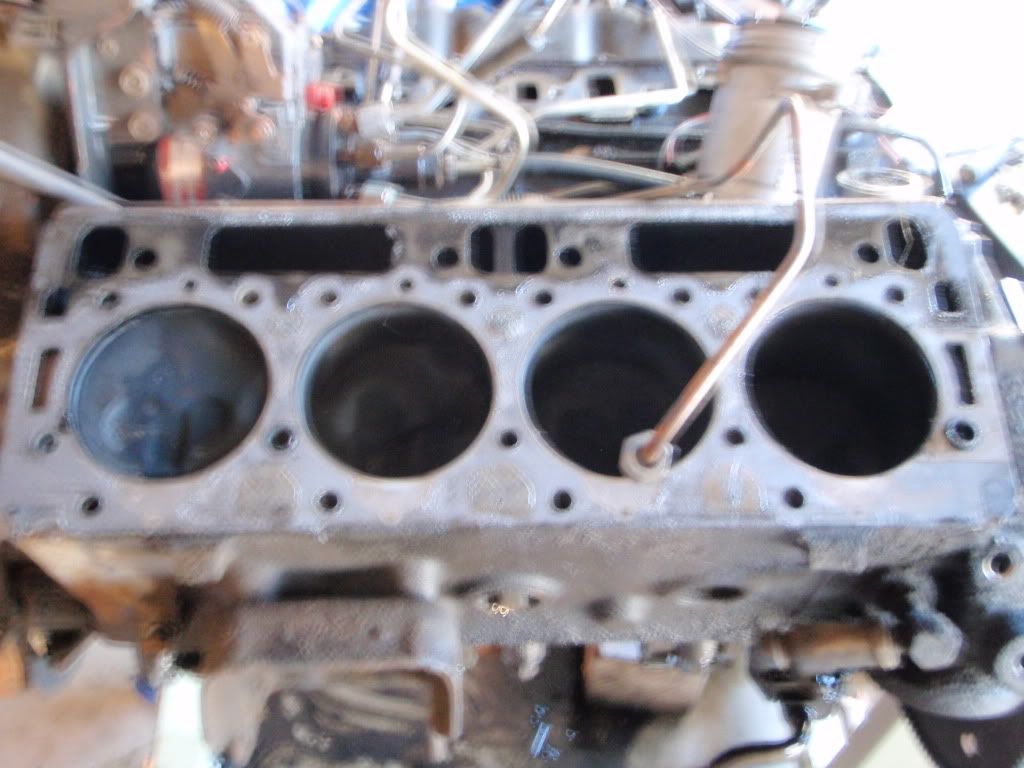

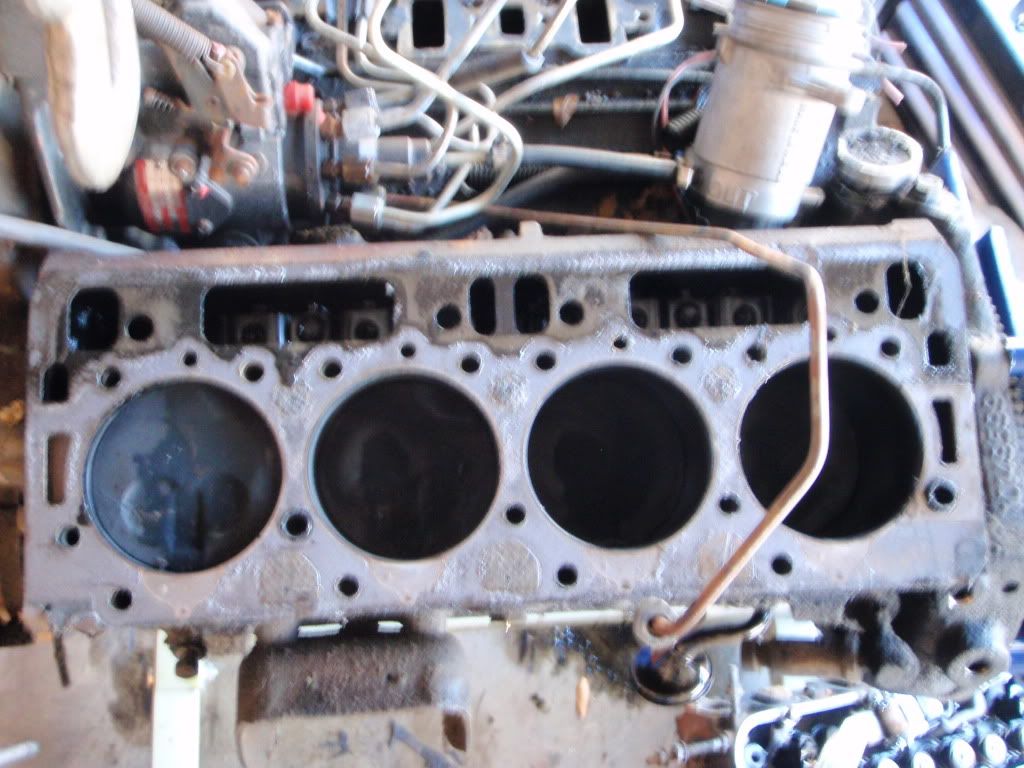

Heads are off now and have some more pics

the next step is cleaning up the work area and the parts, sandblaster for the external parts i think? After that I want to pull the pre-cups out, how do I do that? Once the injector socket arrives I'll pull those out as well and begin searching for a machine shop to clean/test the block and heads. Will also get them to machine a groove for the fire rings, or might do that myself.

Heads are off now and have some more pics

the next step is cleaning up the work area and the parts, sandblaster for the external parts i think? After that I want to pull the pre-cups out, how do I do that? Once the injector socket arrives I'll pull those out as well and begin searching for a machine shop to clean/test the block and heads. Will also get them to machine a groove for the fire rings, or might do that myself.

Paveltolz

Доверяй, но проверяй

Bill Heath is working with cams these days with great results. Give him a call to get one ordered as they aren't on the web page yet.

NVW

Well-Known Member

Once the injectors are out you can use a brass punch through that hole and drive the pre cups out.

red

Being a lake bum in Texas

Thank you for the heads up on the cam from heath I'll give him a call this afternoon.

Thank you, sounds pretty simple to pop the pre-cups out then.

Contacting ARP to get the studs to use on the main once I make/install the girdle. Figure the block has been lucky so far, might as well upgrade it to make sure it stays that way.

By the way does anyone know which turbo this is? Shaft seems solid and spins freely so will be putting it up for sale.

Thank you, sounds pretty simple to pop the pre-cups out then.

Contacting ARP to get the studs to use on the main once I make/install the girdle. Figure the block has been lucky so far, might as well upgrade it to make sure it stays that way.

By the way does anyone know which turbo this is? Shaft seems solid and spins freely so will be putting it up for sale.

Jorge6.5

Well-Known Member

Appears to be a gm3 turbo. Dont waste your time with these gm turbos, they are junk and choke out the engine. That turbo might be good enough for my lawn mower haha lol

Jorge6.5

Well-Known Member

I just took some second looks at the turbo, might be a gm4. I just noticed that it has a vacuum actuator and not spring actuator like the gm3 has. Regardless still a junk turbo and it appears that some one had wired the waste gate shut, real bad news.

red

Being a lake bum in Texas

I have no intentions of running a gm series turbo, just trying to figure out which model this is. to my knowledge it seems to be in good shape, will be posting it up for sale. I'm planning to run a ATT on this motor since the truck does get used for towing.

Ordered the studs for the main cap outer bolts, next need to pick up some angle iron then get to cutting/drilling to make the girdle. Leaning towards not dropping the block off at a machine shop to have them check out the block and cut the fire ring grooves. I'd be too tempted to get the block honed, new piston rings, and scat crank. With the block not being a new casting I dont want to put too much into the bottom end in case it decides to go down the road. Figure I'll add the girdle and studs to help, but after that I'll reinstall the oil pan then clean up the underside of the motor. Once the bottom is buttoned up I'll proceed to the heads and getting the fire rings cut/installed. Do any of our vendors sell diamond pre-cups?

Ordered the studs for the main cap outer bolts, next need to pick up some angle iron then get to cutting/drilling to make the girdle. Leaning towards not dropping the block off at a machine shop to have them check out the block and cut the fire ring grooves. I'd be too tempted to get the block honed, new piston rings, and scat crank. With the block not being a new casting I dont want to put too much into the bottom end in case it decides to go down the road. Figure I'll add the girdle and studs to help, but after that I'll reinstall the oil pan then clean up the underside of the motor. Once the bottom is buttoned up I'll proceed to the heads and getting the fire rings cut/installed. Do any of our vendors sell diamond pre-cups?

DZZ71

"Living The 6.5 Dream"

I would also put in the studs and gurdle in the bottem end. I strongly disagree with warwagon about leaving it with stock bolts.

ak diesel driver

6.5 driver

if it's a higher mileage motor that is crack free chances are pretty good it will stay that way

red

Being a lake bum in Texas

Personal preference I'd rather have the better clamping force that the studs provide and the added strength that the girdle will provide as well. I will only be torquing the studs to stock specs, since added pressure would increase the likelihood of cracks to my knowledge.

The gaskets have arrived, still waiting for the studs to be delivered. Also ordered new freeze plugs, I dont notice any leaks but figure since I have the motor out might as well.

The gaskets have arrived, still waiting for the studs to be delivered. Also ordered new freeze plugs, I dont notice any leaks but figure since I have the motor out might as well.

Paveltolz

Доверяй, но проверяй

Better safe than sorry. It may be a little more expensive but peace of mind is what it is and what you're willing to pay for.

OrionThade

Member

Personal preference I'd rather have the better clamping force that the studs provide and the added strength that the girdle will provide as well. I will only be torquing the studs to stock specs, since added pressure would increase the likelihood of cracks to my knowledge.

The gaskets have arrived, still waiting for the studs to be delivered. Also ordered new freeze plugs, I dont notice any leaks but figure since I have the motor out might as well.

Torquing the studs to "stock spec" may not provide adequate clamping force. I would recommend torquing to ARP specs.

For example, TTY head bolds torque spec is 90 ft/lb plus 1/4 turn (IIRC). ARP head stud torque specs are 115 ft/lb.

sshewins

Jesus Freak

If you look back, 6.2 has some really good info on head gaskets and tourquing. He's playing with TTY and studs. IIRC, he was tourquing around 150 ish. Also there was questions raised on sealing the studs. Like which sealant to use etc... Good read. I think he's using victor reinz (?) Head gaskets.

red

Being a lake bum in Texas

Good to know I'll see if I can find his thread and get some more info on the studs and what works best.

Called Heath Diesel today and ordered their towing cam kit and a fluid damper. Talked with them for awhile about my build and the goals for it. For the amount of boost I plan to run (20ish) they believe I'll be in good shape with the upgrades that are planned on, o-ringing the block would probably be overkill but not a bad idea.

Called Heath Diesel today and ordered their towing cam kit and a fluid damper. Talked with them for awhile about my build and the goals for it. For the amount of boost I plan to run (20ish) they believe I'll be in good shape with the upgrades that are planned on, o-ringing the block would probably be overkill but not a bad idea.

sshewins

Jesus Freak

Yeah, try to find his stuff. He did some testing with fire rings and gaskets. IIRC, most of the gaskets, didn't line up right, cept the vr's. Then he tried different thickness wire. Ya know, there is some major talent here. Very smart.

sshewins

Jesus Freak

Hey red, would you care to elaborate on your conversation with Heath about the towing cam? What's it supposed to do or improve on? Thanks,

red

Being a lake bum in Texas

For your motor being the electronic IP I was told you should expect a significant power increase, about 60hp, with your power from under 3000rpm's to increase the most. They are testing on the mechanical IP right now so they dont have the numbers for them yet. That is for the towing cam, not the performance cam.

1995yukon65

Member

If you dont mind me asking, what did it run ya? I'm getting rdy to start building a 6.2/6.5 hybrid for my truck soon and an upgradedcame sounds interesting if it works as said

sshewins

Jesus Freak

60 HP from just a cam?  On our boat anchors?

On our boat anchors?  And from a towing cam?

And from a towing cam?