btfarm

America First!

Gettin' there Red!:thumbsup:

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

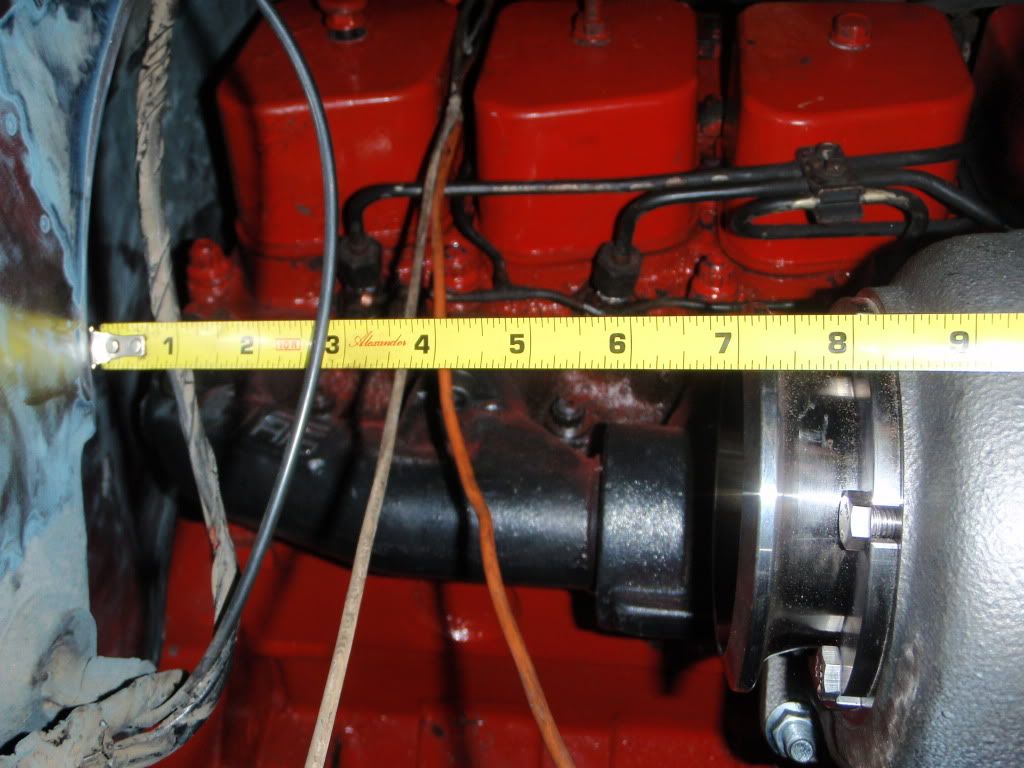

got to working on the plumbing today and checking over everything that i'll need for the engine.

the down pipe needs a slightly sharper bend to clear the firewall, figure a 2nd bend a few inches after the first turn should make enough clearance without affecting the flow much. never thought about flipping the manifold over, currently alot of empty space there.

......but i want working ac in the tow rig lol.

Ahhhhh, ya big sissy. Over rated!

(coming from the guy that moved the dryer and had to make all new AC lines to accomodate go fast parts and WOULD NOT be without AC)

:rof: