red

Being a lake bum in Texas

well figure its time for me to actually start a build thread for this lol. in the process of swapping a 12 valve cummins into my 87 chevy crew cab long bed dually.

donor truck: 95 dodge ram 2500 4wd with an auto tranny. good running motor and decent driver other than the stock turbo being worn out and putting out a max of 7psi of boost with no load.

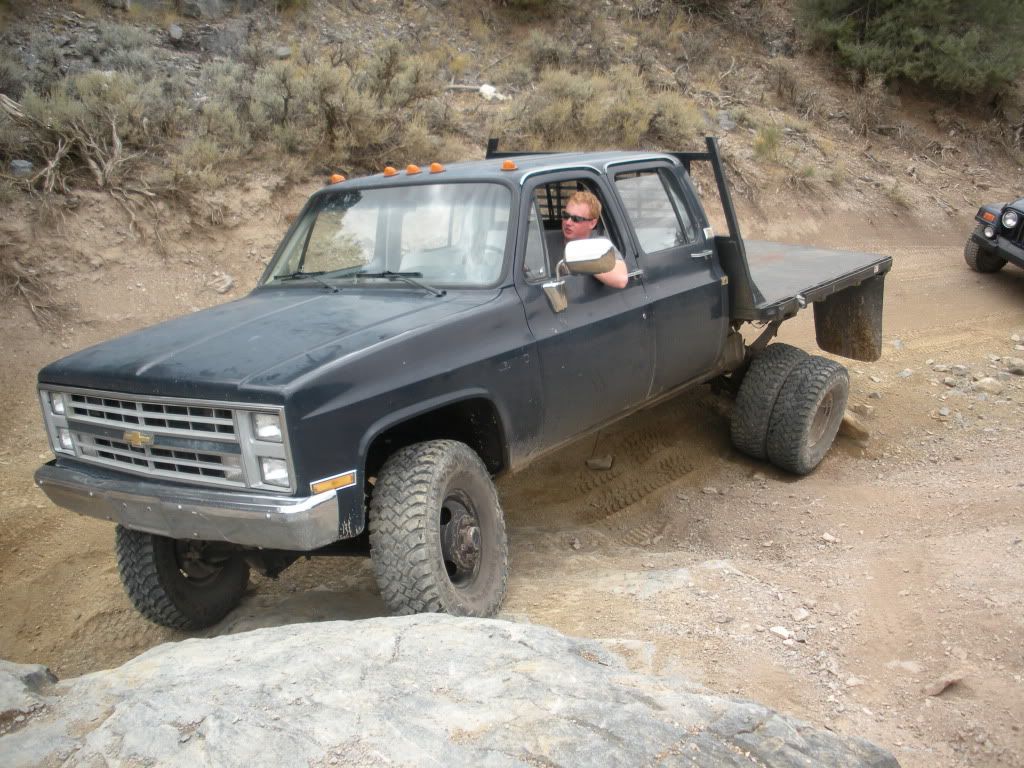

build truck: 87 chevy k30 4wd with a 454, sm465 and np205 t-case. pulls great and goes on almost all of the trails up here in northern utah, but want more power and better than single digit fuel economy which the 454 cant provide. sitting on a 6" lift and 35" tires. initial goal is 800ft/lbs of torque but eventually will go higher than that.

i'd have pics up but the memory card in my camera crashed and corrupted the files so i dont have any pictures from the process of pulling the motor out. so far i've removed the cummins along with the auto tranny and t-case and placed them on a engine stand that attaches to the motor mounts along with the bellhousing, similar to how cumminalong made his stand. the auto tranny and t-case are sold, planning to reuse my np205 and ordering a rebuilt nv4500 that has the 5th gear upgrade. need to decide on a clutch that can handle the planned power yet is still daily driveable.

pulled the head and the pan off of the block and it looks to me like the motor has been rebuilt at some point, way to clean and the clearance of everything i've checked so far are well within the manufactures specs so it looks to me like i lucked out with the purchase. was a great running motor i just pulled it apart to inspect the internals, figure since i have the motor on a stand right now that i might as well, and dont want to have internal engine issues within the next few years.

arp head studs are on the way right now, should be here in the next week. dont think i will do the fire rings yet because i will only be running a single turbo (aurora 3000) for now but when i upgrade to twin turbos i will need to do it then. swap is taking time because of work, sucks to be gone for 3 weeks before i have only 2-3 days to work on it then gone again.

donor truck: 95 dodge ram 2500 4wd with an auto tranny. good running motor and decent driver other than the stock turbo being worn out and putting out a max of 7psi of boost with no load.

build truck: 87 chevy k30 4wd with a 454, sm465 and np205 t-case. pulls great and goes on almost all of the trails up here in northern utah, but want more power and better than single digit fuel economy which the 454 cant provide. sitting on a 6" lift and 35" tires. initial goal is 800ft/lbs of torque but eventually will go higher than that.

i'd have pics up but the memory card in my camera crashed and corrupted the files so i dont have any pictures from the process of pulling the motor out. so far i've removed the cummins along with the auto tranny and t-case and placed them on a engine stand that attaches to the motor mounts along with the bellhousing, similar to how cumminalong made his stand. the auto tranny and t-case are sold, planning to reuse my np205 and ordering a rebuilt nv4500 that has the 5th gear upgrade. need to decide on a clutch that can handle the planned power yet is still daily driveable.

pulled the head and the pan off of the block and it looks to me like the motor has been rebuilt at some point, way to clean and the clearance of everything i've checked so far are well within the manufactures specs so it looks to me like i lucked out with the purchase. was a great running motor i just pulled it apart to inspect the internals, figure since i have the motor on a stand right now that i might as well, and dont want to have internal engine issues within the next few years.

arp head studs are on the way right now, should be here in the next week. dont think i will do the fire rings yet because i will only be running a single turbo (aurora 3000) for now but when i upgrade to twin turbos i will need to do it then. swap is taking time because of work, sucks to be gone for 3 weeks before i have only 2-3 days to work on it then gone again.