Michaeljp86

EVIL GENIUS

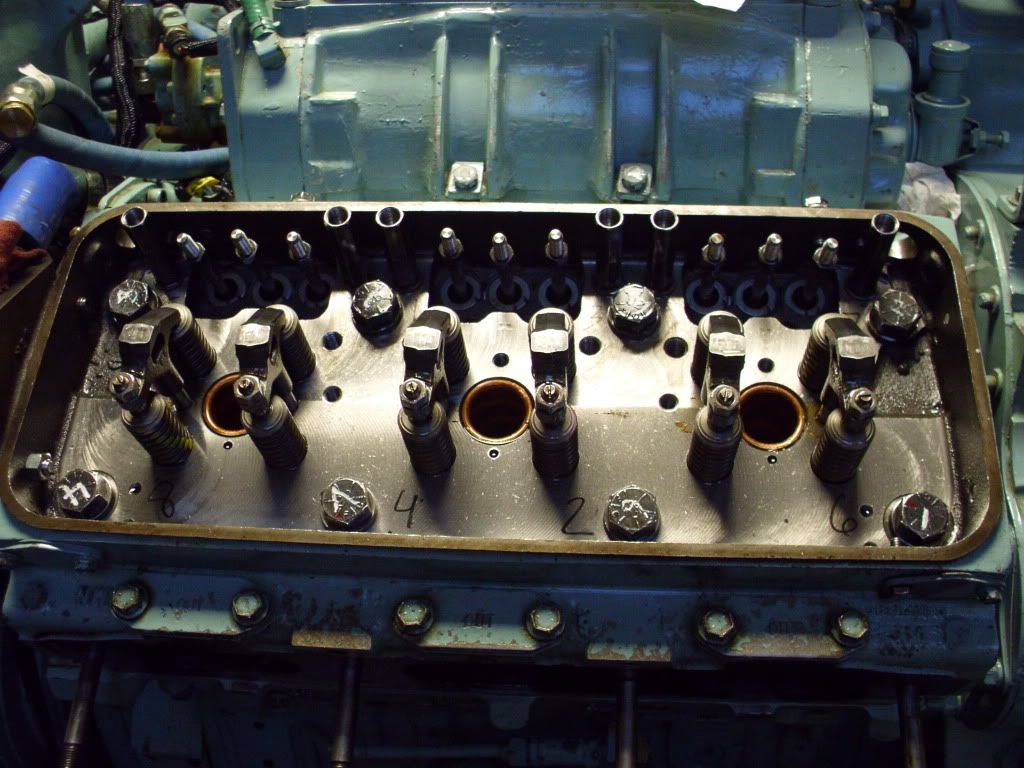

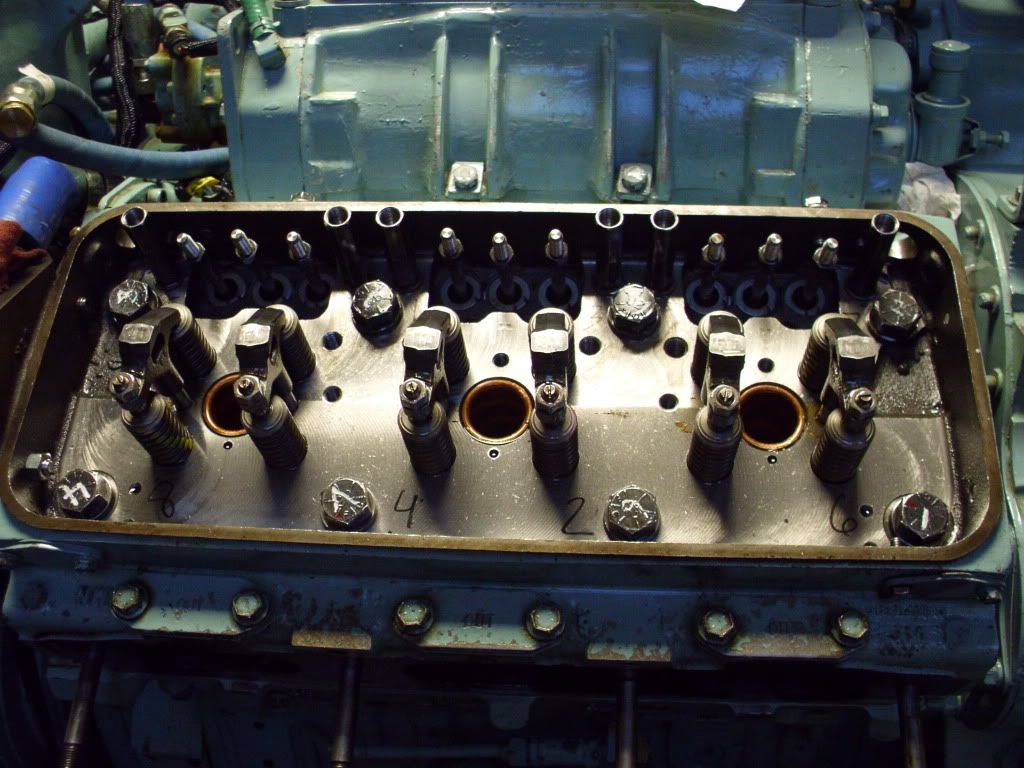

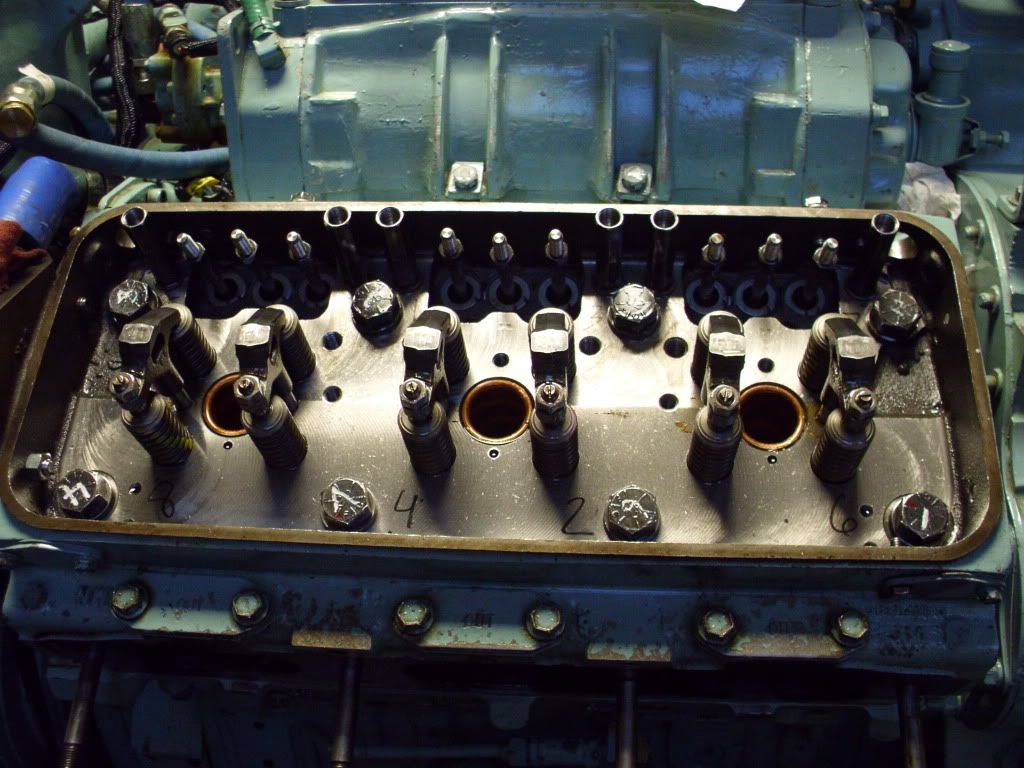

Here's some pictures of the 6v92 we had to rebuild in coast guard machinery technician school.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Nice pics. For those not familiar with real Detroit 2 strokes notice in the second pic, center jug the holes in the cyl. That is how the air enters the cyl as the engine has no intake valves. It's called crankcase scavenging. The air is forced through the holes by the blower and then compressed on the upstroke. The injs(not shown) are camshaft operated as are the 4 ex valves per cyl. There is no central INJ pump. timing is done at the inj with special tool. IMHO the original common rail...

Yep. Are the USCG boats running NA or turbo ?

I drove a few KW's with 8v92t's You could easily crank them up to 475hp with the right injs plus Mario from the Bridgeport ferry knew how tune them just right.

This guy is from Oz and claims to have an 8-92 that's putting out 520hp. I read what injectors he was running in one of the comments. http://www.youtube.com/user/swishyhasbeen

Problem with those Old 2 strokes was they had no low end torque so you needed a driver that knew how to driv eone. You didn't dare stop at a light on a hill with 40 ton on your back or you'd twist the driveshaft right out. Nope had to time your lights well and walk it...

Na, its like any two stroke engine (Dirt bikes) they don't make any power at the bottom end you have to keep them wound up to be in the power band. Sure the blower would suck up about 20% of the power at the top end.All the torque probably got sucked up by driving that huge blower.

Na, its like any two stroke engine (Dirt bikes) they don't make any power at the bottom end you have to keep them wound up to be in the power band. Sure the blower would suck up about 20% of the power at the top end.

Some four stoke diesels are the same way M11 Cummaparts 4 ex. Found out the hard way with my uncles truck pulling a rig pump and tank for his service rig on soft dirt roads. I was mistakenly under the impression that you could lug all 4 stroke in-lines' a little. The mechanic told me with no pyrometer (which should be a standard in all trucks) too keep it above 1500 on the M11's, and I was waiting until 1300-1400 before I'd down shift.

I've been told that the detroit 2 strokes when properly set up can handle 5000 rpm also, the 8-71 on the rig regularly sings to 3200 when tripping out tubing. I would like to have 4-53 in my truck with the jakes singing from 5,000. That would piss off a few PITA neighbor's.